In the realm of precision fabrication, technological advancements have been pivotal to industry evolution. Amongst these advancements, laser cutting has taken centre stage, offering a myriad of benefits that enhance both the efficiency and accuracy of manufacturing processes. In particular, the city of Brisbane has witnessed a surge in the adoption of this technology, revolutionizing the local manufacturing landscape.

Origins and Evolution of Laser Technology

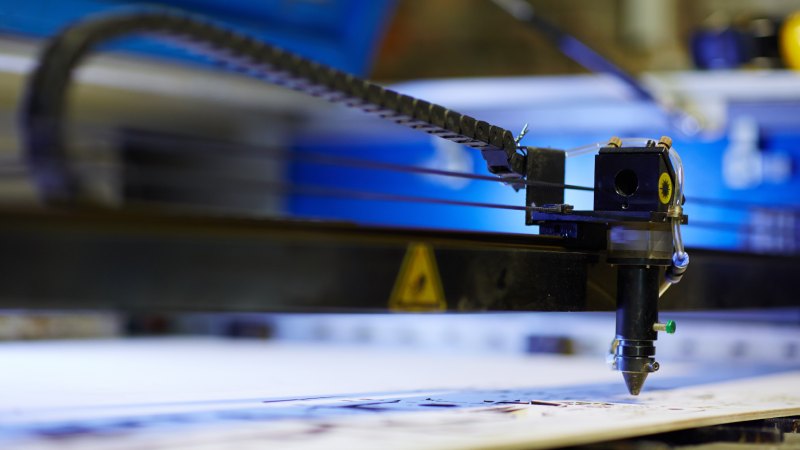

Since its inception in the 1960s, laser technology has seen significant developments. The principle of using a high-powered laser allows for the precise cutting of various materials, including metals, plastics, and composites. The process is highly automated and computer-controlled, resulting in precise cuts that are often impossible to achieve through traditional methods.

Benefits of Laser Cutting in Precision Fabrication

The benefits of laser cutting in Brisbane based fabricators are multifaceted. The precision achievable with laser cutting is unparalleled, allowing for intricate details and complex shapes to be produced with smooth edges and consistent quality. Moreover, the speed at which laser cutting operates significantly reduces production times, enabling faster turnarounds for projects.

Impact on Local Industries

Brisbane’s adoption of laser cutting technology has had a profound impact on local industries. Sectors such as aerospace, automotive, construction, and marine have all benefited from the improved efficiency and accuracy the technology brings. This has not only bolstered the competitiveness of Brisbane-based businesses but has also driven innovation within these sectors.

Material Flexibility and Efficiency

Laser cutting offers incredible versatility in terms of the materials it can process. Metals like steel, aluminium, and copper, as well as non-metallic materials, can all be cut with precision. The technology’s efficiency is further exemplified in its ability to handle various material thicknesses without the need for tool changes, optimizing the manufacturing process.

Environmental Considerations

Precision fabrication via laser cutting is also highly regarded for its environmental benefits. The process minimizes waste through precise cuts that optimize material usage. Additionally, because it is a contactless process, there is less wear and tear on cutting tools, reducing the frequency of replacements and thus the associated waste.

Economic Impacts of Laser Cutting

The economic impacts of integrating laser cutting into precision fabrication cannot be overstated. For Brisbane’s manufacturing businesses, investment in laser cutting technology has led to cost savings through reduced labor requirements and decreased material wastage. This not only positively affects a company’s bottom line but also offers cost benefits to the end consumer.

Training and Workforce Development

Adopting laser cutting technology necessitates skilled operators. Thus, there’s a growing demand in Brisbane for professionals trained in this high-tech field. This demand has encouraged vocational and technical training programs to adapt, fostering a workforce skilled in the latest manufacturing technologies.

Enhancing Design Possibilities

The precision fabrication capabilities of laser cutting have opened up new horizons in design possibilities. Designers and engineers in Brisbane are now able to experiment with complex geometries and intricate patterns that were once deemed impractical or too costly to produce.

Industry Specific Applications

Each industry has its specific requirements, and laser cutting has proven adaptable to meet these diverse needs. For example, in the field of medical equipment manufacturing, which requires strict adherence to tolerances, laser cutting ensures accurate parts that conform to rigorous standards.

Consistency and Reproducibility

One of the most significant advantages of laser cutting is the consistency and reproducibility it offers. Once a design is programmed, fabricators in Brisbane can expect every cut to match the original precisely, which is indispensable for mass production and quality control.

Challenges and Mitigation Strategies

Despite its many benefits, laser cutting does come with its own set of challenges. The initial costs of machinery and maintenance can be high. However, Brisbane’s manufacturers mitigate these expenses by investing in high-quality machines that offer greater longevity and seeking out local expertise for regular maintenance and repair.

Future Prospects of Laser Cutting in Brisbane

The future of laser cutting in Brisbane looks bright, with ongoing technological developments promising even greater precision, efficiency, and material compatibility. As local manufacturers continue to embrace these advancements, we can expect Brisbane to maintain its position at the forefront of precision fabrication.

The Verdict on Laser Cutting

Laser cutting has undoubtedly revolutionized the field of precision fabrication in Brisbane, offering a level of precision, efficiency, and versatility that traditional methods struggle to match. As an integral component in the progression of manufacturing, it supports innovation and drives the success of a wide array of industries.

In conclusion, the adoption of laser cutting Brisbane standards for precision and innovation reflects the city’s commitment to embracing modern technologies. As a leader in manufacturing processes, Brisbane displays not only remarkable skill in production but also a forward-thinking approach to industrial growth and development.